Stretch bending

One of the latest, most advanced cold bending techniques for aluminium is stretch bending.

When conventional bending processes reach their limits in terms of quality and physics, stretch bending is the answer.

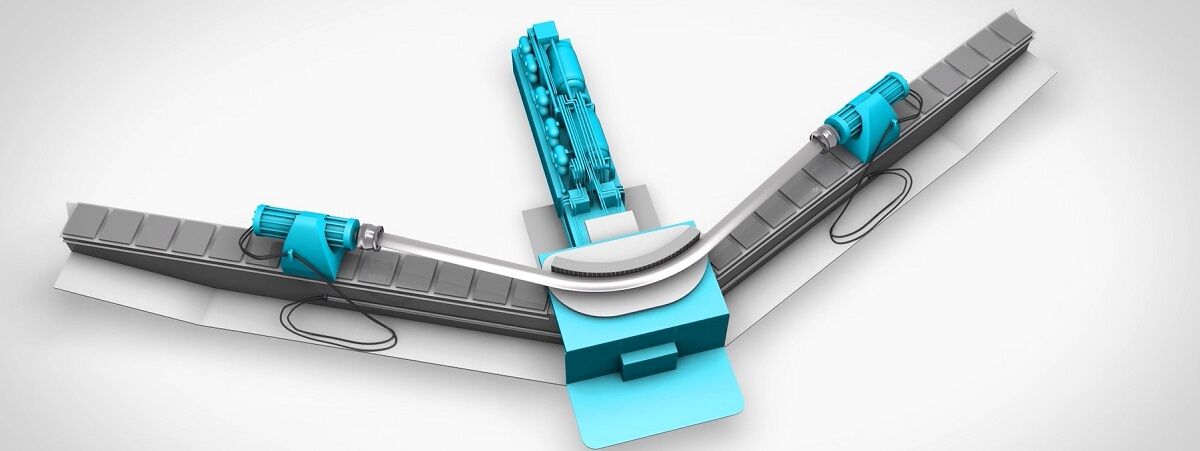

Stretch bending is a very precise technique developed in the aerospace industry. Here, the surface quality of the bent product is very important and this remains in great condition with stretch bending. This bending technique requires a special machine, tooling and solid craftsmanship. Kersten makes this advanced bending technique available to other industries outside aviation.

Kersten develops and produces its own special tools for this technique with which even the most delicate aluminum profiles can be bent. Because there is no friction between the profile and the machine, the surface remains in optimal condition and distortion of the cross section is reduced to an absolute minimum. Even when very small radii are involved.

During stretch bending, the profile is first tensioned by stretching it before being pulled around a mould. The extra stretch helps prevent cracks from forming on the outside of the bend, waves from forming on the side surfaces and compression on the inside of the bend. For example, aluminium façade profiles (250 x 50 x 3 mm) can be bent around the strong axis with a quality previously unachievable with conventional bending. The use of fixed bending contour tools also enables very high repeat accuracies to be achieved within a bending series and the same material batch. Depending on the profile size and radius, foiled and coated profiles can also be bent.

While stretch bending technology was previously mainly used for large series in the automotive industry and aircraft construction and was usually only intended for bending one type of product, Kersten makes stretch bending of aluminium profiles also available for smaller series and projects. For example, for facade construction.

Capacities:

- Tubes and profiles up to 500mm wide.

- Aluminium extrusion profiles, aerofoil fins, steel and stainless steel tubes and profiles

- Tubes and profiles with a maximum length of 13 metres

- Additional operations such as machining, welding and heat and surface treatments. (incl. special finishes, e.g. wood-look finish).